- info@zebaearth.org

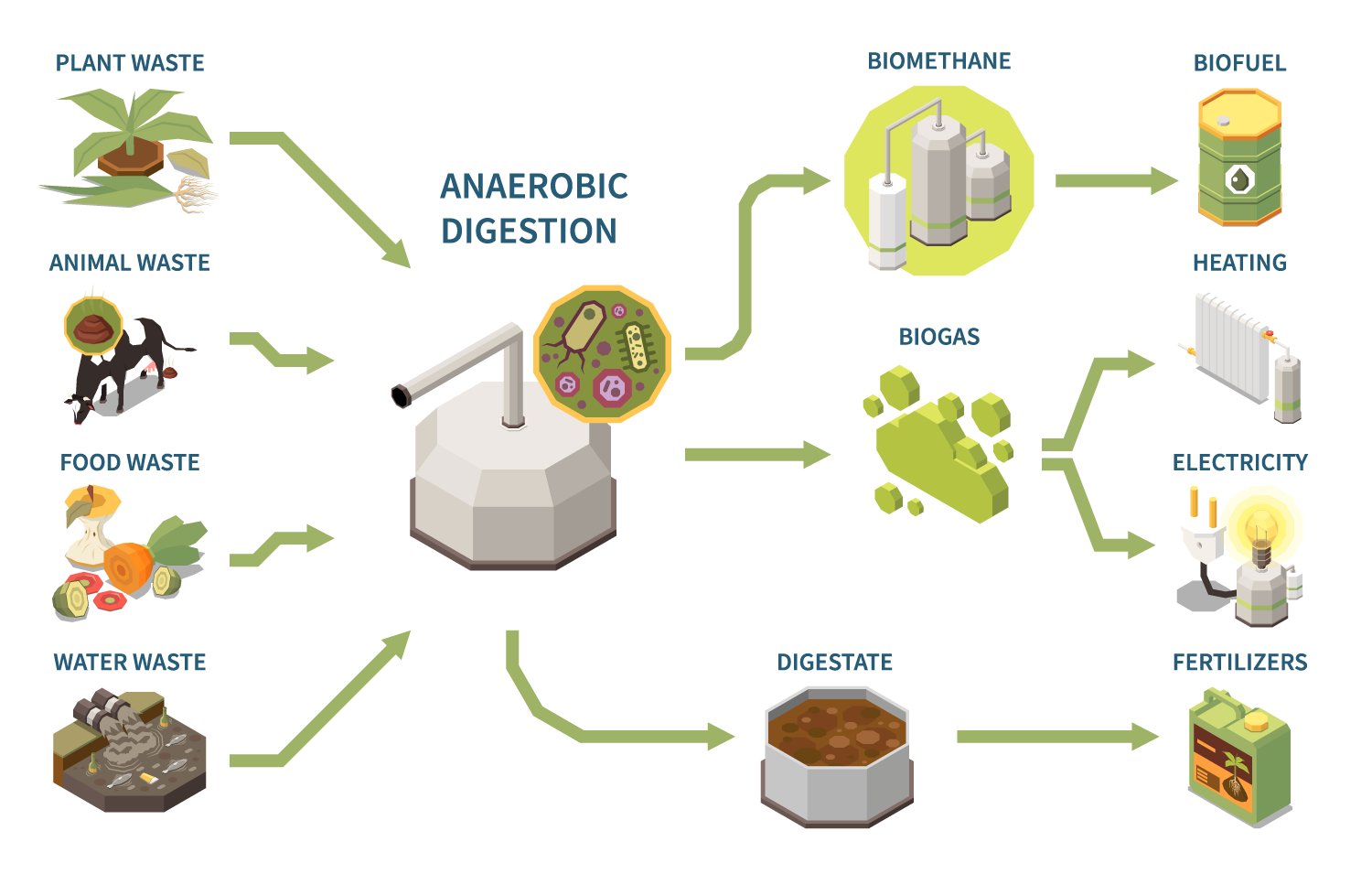

Biogas is a renewable energy source that is produced by anaerobic digestion, a process in which bacteria break down organic matter in the absence of oxygen. This process can occur naturally, such as in wetlands and landfills, or it can be artificially produced in anaerobic digesters.

ZebaEarth is a waste to energy company that specializes in the production of biogas. The company’s biogas manufacturing process begins with the collection of organic waste, such as food scraps, manure, and agricultural waste. This waste is then transported to the company’s anaerobic digesters, where it is broken down by bacteria to produce biogas.

The biogas produced by ZebaEarth is a clean, renewable energy source that can be used to generate electricity, heat homes and businesses, and power vehicles. The company is committed to providing innovative renewable energy solutions that help to reduce our reliance on fossil fuels and protect the environment.

The digestate is used as a fertilizer or compost.

The first step is to collect the feedstock, which can be any organic material, such as agricultural waste, food waste, or manure. ZebaEarth sources its feedstock from a variety of sources, including farms, food processing plants, and wastewater treatment plants.

The feedstock is then pretreated to break it down into smaller pieces and to remove any contaminants. This process can involve physical, chemical, or biological methods. Physical methods, such as grinding or chopping, are used to break down the feedstock. Chemical methods, such as acid hydrolysis, are used to break down the bonds in the organic molecules.

Anaerobic digestion is a process that occurs in the absence of oxygen. Bacteria in the digester break down the organic matter in the feedstock, producing biogas as a byproduct. The biogas produced by anaerobic digestion is typically about 60% methane and 40% carbon dioxide.

The biogas produced by anaerobic digestion may contain impurities, such as hydrogen sulfide and water vapor. These impurities can be removed using a variety of methods, such as absorption, adsorption, and membrane separation.

The purified biogas is then compressed to a high pressure, which increases its density and makes it easier to transport and store. The compressed biogas is typically stored in cylinders or tanks at pressures of up to 250 bar.

During the anaerobic digestion process used to produce biogas, the organic waste undergoes decomposition by microorganisms. As a result, nutrient-rich digestate is generated, which can be further processed and transformed into biofertilizers.

Biofertilizers derived from biogas production offer several advantages. They contain beneficial microorganisms such as bacteria, fungi, and algae that enhance soil fertility, nutrient availability, and overall plant growth. These biofertilizers provide organic matter and essential nutrients to the soil, promoting sustainable agriculture practices and reducing reliance on synthetic fertilizers.

ZebaEarth, being a waste-to-energy and renewable energy company, is dedicated to maximizing the value of organic waste through biogas manufacturing, and the production of biofertilizers aligns with their commitment to sustainable agricultural solutions.

Biogas is burned in an internal combustion engine to generate mechanical energy. This mechanical energy is then used to turn a generator, which produces electricity.

Biogas is burned in a gas turbine to generate electricity. Gas turbines are more efficient than internal combustion engines, but they are also more expensive.

Microturbines are small, gas-fired turbines that can be used to generate electricity on-site. Microturbines are a good option for small businesses and homes that want to generate their own electricity.

Biogas is a renewable energy source, which means that it can be replenished over time. This makes it a sustainable alternative to fossil fuels, which are a finite resource.

Biogas is a clean-burning fuel, which means that it produces fewer emissions than fossil fuels. This makes it a good choice for businesses and homes that want to reduce their environmental impact.

The cost of generating electricity from biogas can be lower than the cost of generating electricity from fossil fuels. This makes biogas a cost-effective option for businesses and homes that are looking to save money on their energy bills.

We provide a start to finish solution that converts organic waste into BioCNG and organic manure/soil conditioner that results in increased industrial and farmer productivity and a cleaner environment.